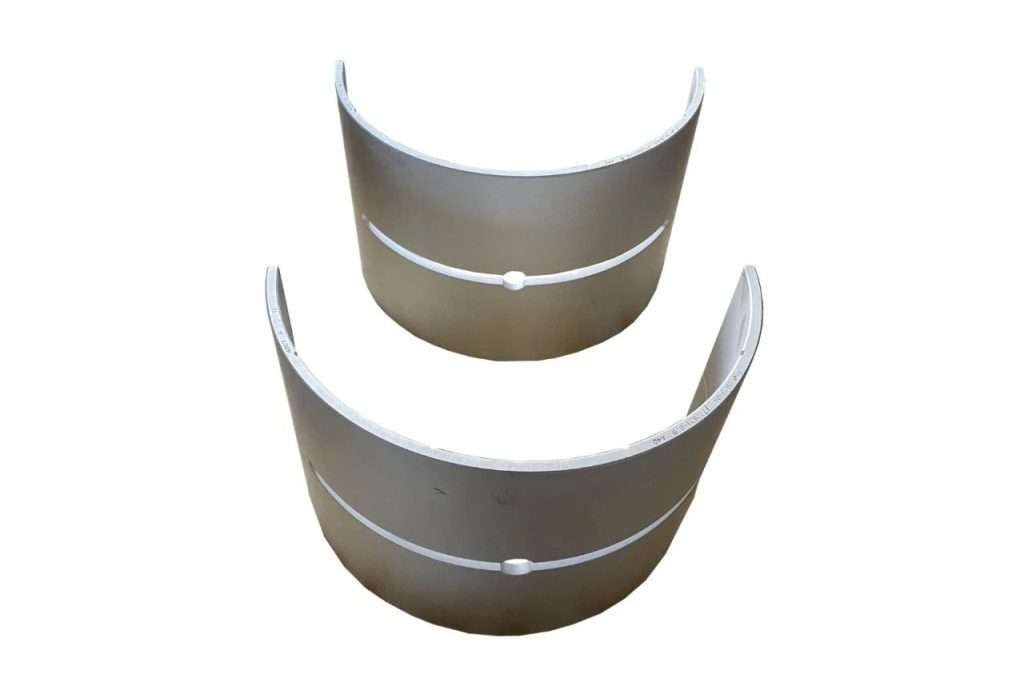

Recommended inventory of bearing shell for sale for S35MC- diesel engine main bearing shells/crosshead bearing shells/crank pin bearing shells

| NAME | PART NO./DRAW NO. | QTY.&QUA. |

| MAIN BEARING ,COMPLETE | P91210-0164-157 1847572-6.0&1847573-8.0 | 9 Original New |

| CRANKPIN BEARING SHELL | P90401-0145-318 1847280-2.1&1847281-4.1 | 16 Original New |

| CROSSHEAD BEARING, UPPER | P90401-0145-379 1722647-9.6 | 16 Original New |

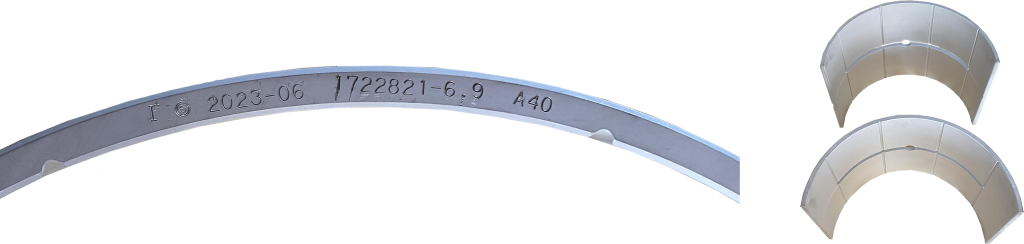

| CROSSHEAD BEARING,LOWER | P90401-0145-414 1722821-6.4 | 11 Original New |

MAIN BEARING ,COMPLETE

CROSSHEAD BEARING, UPPER

CROSSHEAD BEARING,LOWER

Crankpin Bearing Shells

Not only for S35MC, Sino-Ocean Marine but also stocks a lots of bearings which are suitble for other engine types, such as S50MC-C, S60MC-C, S70MC-C, etc. Our stock bearing kinds include Main bearing, Connecting rod bearing, Crosshead bearing, etc. Genuine quality with competitve prices!

If you are interested in them, please don’t hesitate to contact with us.

Tips:

How to determine whether these diesel engine main bearings,crosshead bearing shells, and crank pin bearing shells

need to be replaced?

To determine whether the main bearings, crosshead bearing shells, and crank pin bearing shells of a diesel engine need to be replaced, the following aspects can be inspected:

- Noise and vibration: If the bearing fails, it usually produces abnormal noise and vibration. If these noises and vibrations suddenly intensify, it may be a sign that the bearing is about to fail.

- Temperature: Check whether the bearing temperature is normal. If the bearing temperature is too high, it may be due to poor lubrication or bearing wear and other issues.

- Clearance: The bearing gradually wears during operation, resulting in an increase in clearance. If the clearance is too large, it will affect the normal operation of the bearing and need to be replaced.

- Lubrication: Regularly check the lubrication of the bearing. If there is insufficient lubrication or the lubricating oil has deteriorated, it will accelerate the wear of the bearing.

- Appearance: Check whether the appearance of the bearing has wear, cracks, rust, and other abnormal conditions. If these abnormal conditions are found, it is necessary to replace the bearing in time.